Material Options

Which is right for your application?

Which is right for your application?

After years of working with hundreds of different casting materials, and feedback from multiple hobbyist, I've settled on four materials that provide an array of differing properties and cost. Since the reptile and aquarium hobby has thousands of different types of animals, having a wider array of materials available will help ensure you get what your specific design calls for. If you are building a dart frog enclosure, no need to purchase a pricier material that can withstand alligator claws. Conversely, if you're building for a large or aggressive animal, you won't want something that was designed for just small geckos and frogs.

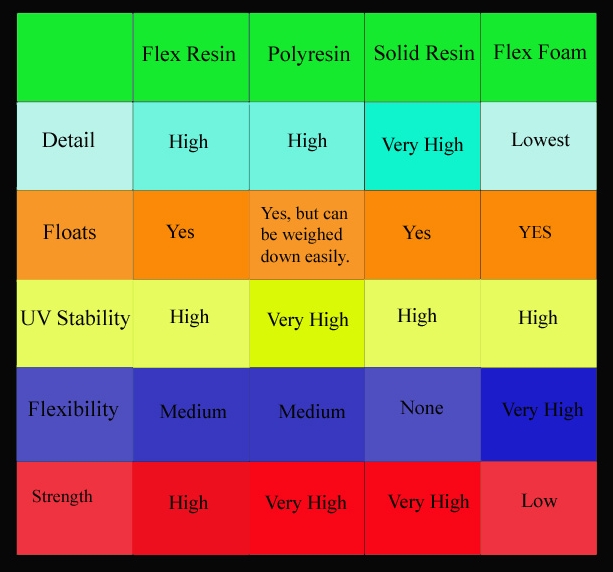

I feel these four materials allow for a good diversity in the product's flexibility, detail, UV resistance, buoyancy, cutting ease, and being solid/hollow. Below you will find the properties of each material discussed in detail and a chart comparing the different properties.

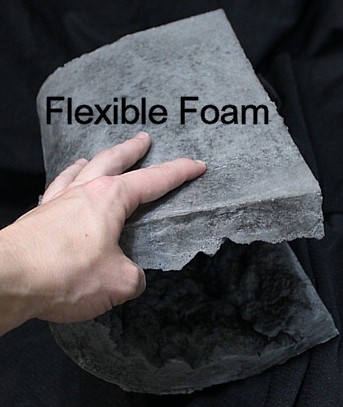

Flexible Foam

The flexible foam is best thought of as a very dense sponge like material. It is the least costly of the three material options and is ideal for use in mostly terrariums and vivariums. The advantage of the flexible foam is that it is the easiest to cut, carve, compress, get into an aquarium past the trim, and make custom designs with. This material is only available for the some of the backgrounds. They are all solid which keeps animals from getting under/behind them.

The main reason I chose to use this material was because it wicks water. The open cells of the foam matrix allow water to move through the foam and holes can be cut into the foam easily; properties which are ideal for many planted vivariums. The ease of cutting the Flexible Foam allows you to place plants directly into crevices or holes without much hassle. The cellular nature of the exterior surface can allow small amounts of soil to become trapped in them, while still allowing water to migrate through the foam. I've found this aids greatly in the growth of plant roots and especially mosses as the texture, even on the smooth rock casts, allows the plants and mosses to grab and take root.

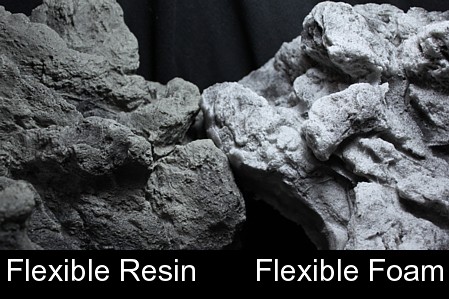

The two backdraws of this material are that it floats and it has a lowered detail compared to the other materials. The foam can be used underwater, but I've found to be very challenging to get it to stay down. The only way I've found is to silicone or foam it together as a larger structure, and then glue that structure to the glass. The texture detail comparisons picture is primarily why most people opt for the Flexible Resin filled with foam. While slightly higher in cost, Flexible Resin casts give much of the Flexible Foam's properties but with a higher detail.

The flexible foam is best thought of as a very dense sponge like material. It is the least costly of the three material options and is ideal for use in mostly terrariums and vivariums. The advantage of the flexible foam is that it is the easiest to cut, carve, compress, get into an aquarium past the trim, and make custom designs with. This material is only available for the some of the backgrounds. They are all solid which keeps animals from getting under/behind them.

The main reason I chose to use this material was because it wicks water. The open cells of the foam matrix allow water to move through the foam and holes can be cut into the foam easily; properties which are ideal for many planted vivariums. The ease of cutting the Flexible Foam allows you to place plants directly into crevices or holes without much hassle. The cellular nature of the exterior surface can allow small amounts of soil to become trapped in them, while still allowing water to migrate through the foam. I've found this aids greatly in the growth of plant roots and especially mosses as the texture, even on the smooth rock casts, allows the plants and mosses to grab and take root.

The two backdraws of this material are that it floats and it has a lowered detail compared to the other materials. The foam can be used underwater, but I've found to be very challenging to get it to stay down. The only way I've found is to silicone or foam it together as a larger structure, and then glue that structure to the glass. The texture detail comparisons picture is primarily why most people opt for the Flexible Resin filled with foam. While slightly higher in cost, Flexible Resin casts give much of the Flexible Foam's properties but with a higher detail.

Flexible Resin

This Flexible Resin is the compromise between the high durability and texture of the Poly Resin, and the ease of cutting and customization of the Flexible Foam. Casts made from this material are filled solid with the flexible foam, but coated in a detail layer of a flexible resin that gives a very high level of detail to each cast and improved durability over the Flexible Foam.

Cutting this material is harder than the Flexible Foam, but in most cases it's nothing a sharp, non-serrated knife or small handsaw can't handle. Once past the resin detail layer, I use a large box cutter blade to cut the foam interior. As it's filled with foam, it will still float, less so than the Flexible Foam, but you need to silicone or foam for use underwater.

The exterior surface coating is a flexible resin and it's ability to give and bend slightly allows it to be used with a wide array of animals. Unless your design is for an iguana, aquatic turtle, or other large clawed animal, this material will work very well. Most people have opted to use this material for dart frog vivariums and snake exhibits, but it can be used with a most other reptiles/amphibians.

This Flexible Resin is the compromise between the high durability and texture of the Poly Resin, and the ease of cutting and customization of the Flexible Foam. Casts made from this material are filled solid with the flexible foam, but coated in a detail layer of a flexible resin that gives a very high level of detail to each cast and improved durability over the Flexible Foam.

Cutting this material is harder than the Flexible Foam, but in most cases it's nothing a sharp, non-serrated knife or small handsaw can't handle. Once past the resin detail layer, I use a large box cutter blade to cut the foam interior. As it's filled with foam, it will still float, less so than the Flexible Foam, but you need to silicone or foam for use underwater.

The exterior surface coating is a flexible resin and it's ability to give and bend slightly allows it to be used with a wide array of animals. Unless your design is for an iguana, aquatic turtle, or other large clawed animal, this material will work very well. Most people have opted to use this material for dart frog vivariums and snake exhibits, but it can be used with a most other reptiles/amphibians.

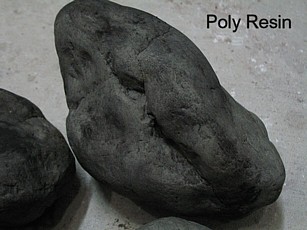

Poly-Resin

This is the highest quality material and each cast requires over 24 hours produce and is seriously strong. It has a slight flex to it, while still being very strong and hard. Casts made from this material have the same level of detail as the Flexible Resin, but are stronger, harder, more scratch resistant, hollow, and can be made to sink by siliconing in small rocks.

Casts made of the Poly-Resin are the ideal material for use in the aquarium or underwater sections of the vivarium/paludarium. Aquariums, aquatic turtles, iguanas, adult bearded dragons, alligators/crocs, tegus, and other habitat intensive animals are what this material was designed for, or anyone who wants a hollow hide rock. Unlike the Flexible Resin, the Poly-Resin doesn't require a foam support, so casts can be used as hide rocks without having to carve out a hide in the foam. When cutting this material it is best done with a hacksaw or sheers in the thinner sections. In most cases a knife won't work as easily as it does with the other two materials.

Backgrounds can be made with this material and supported with flexible foam similar to the Flexible Resin backgrounds, however it may prove challenging to get the background into the aquarium if the glass dimensions are close to the cast's as this combination yields a very rigid background. It can be done, and I've made multiple solid backgrounds this way, but usually for backgrounds or rocks that are to be incorporated into a larger design as getting the background past the black trim can prove challenging.

This is the highest quality material and each cast requires over 24 hours produce and is seriously strong. It has a slight flex to it, while still being very strong and hard. Casts made from this material have the same level of detail as the Flexible Resin, but are stronger, harder, more scratch resistant, hollow, and can be made to sink by siliconing in small rocks.

Casts made of the Poly-Resin are the ideal material for use in the aquarium or underwater sections of the vivarium/paludarium. Aquariums, aquatic turtles, iguanas, adult bearded dragons, alligators/crocs, tegus, and other habitat intensive animals are what this material was designed for, or anyone who wants a hollow hide rock. Unlike the Flexible Resin, the Poly-Resin doesn't require a foam support, so casts can be used as hide rocks without having to carve out a hide in the foam. When cutting this material it is best done with a hacksaw or sheers in the thinner sections. In most cases a knife won't work as easily as it does with the other two materials.

Backgrounds can be made with this material and supported with flexible foam similar to the Flexible Resin backgrounds, however it may prove challenging to get the background into the aquarium if the glass dimensions are close to the cast's as this combination yields a very rigid background. It can be done, and I've made multiple solid backgrounds this way, but usually for backgrounds or rocks that are to be incorporated into a larger design as getting the background past the black trim can prove challenging.

Low cost. Floats. Easy to Cut. Lowest Detail.

Best detail. Floats. Cuts with knife/saw.

Hollow. Can be made DENSE to sink for aquariums.

Solid Resin

The solid resin is designed to be an ultra-high detail cast but still lighter than real rocks. These casts are solid and heavier than the flexible foam but still light enough to float. If you are planning to use these in the aquarium you will need to silicone, epoxy, or foam them to keep them down.

The solid resin is designed to be an ultra-high detail cast but still lighter than real rocks. These casts are solid and heavier than the flexible foam but still light enough to float. If you are planning to use these in the aquarium you will need to silicone, epoxy, or foam them to keep them down.

Solid Resin

Strong. Floats . Solid. Excellent detail.

Polyresin discontinued until cooler weather. Too hot to use until Texas is back down to mid 60s. Sets up too fast when garage is hot and ruins all the details. The Flex Resin doesn't care and works better in the heat.